The trianglelab has always been concerned about product quality.We are developing products and working hard to improve the quality.We will not abandon our reputation because of many cheap products on the market.It is believed that only high quality products can ensure the quality of your work and bring safety to your work.

Some of our products may be more expensive than others,but please believe in our quality and believe that you will not regret when you receive the goods.

STD6-Liquid Cooling

Features:

Maximum Continuous Flow up to 95mm³/s.

Solid Structure.Ultra High Flowrate.Lightweight.Compact.

Installation tutorial & STL & STD6 Packaging List:

Introduction

STD6 is a high-performance, high-flowrate hot-end. It is compact in size, light in weight and high in heating power. Thanks to the cylindrical high-power ceramic heating element wrapped in the copper alloy hot-melt section, the heat transfer path is very short, the temperature rise is fast, and the flow rate is high. It can reach a maximum continuous flow rate of 95 cubic millimeters per second.

Complete and seamless design of filament path, from the inlet to the nozzle is completed by a single stainless-steel tube, reducing the jamming and filament feeding resistance, and more wear-resistant than copper alloy and brass parts.

Adapt to a variety of mounting methods. You can mount it from the top or from rear and even use the traditional V6 style groove Mount.

It is easy to mount the direct drive extruder from the top or use the Bowden adapter to feed filament remotely.

It is compatible with common V6 style nozzles and volcano style nozzles. which can effectively increase flexibility and reduce operating costs. It is suitable for more scenarios and types of filament material.

When using the standard V6 0.4 nozzle you can print fine detail parts like a traditional hot-end and because of the unparalleled burst flowrate you can greatly reduce the printing time by increasing the extruded width of the infill and inner perimeters.

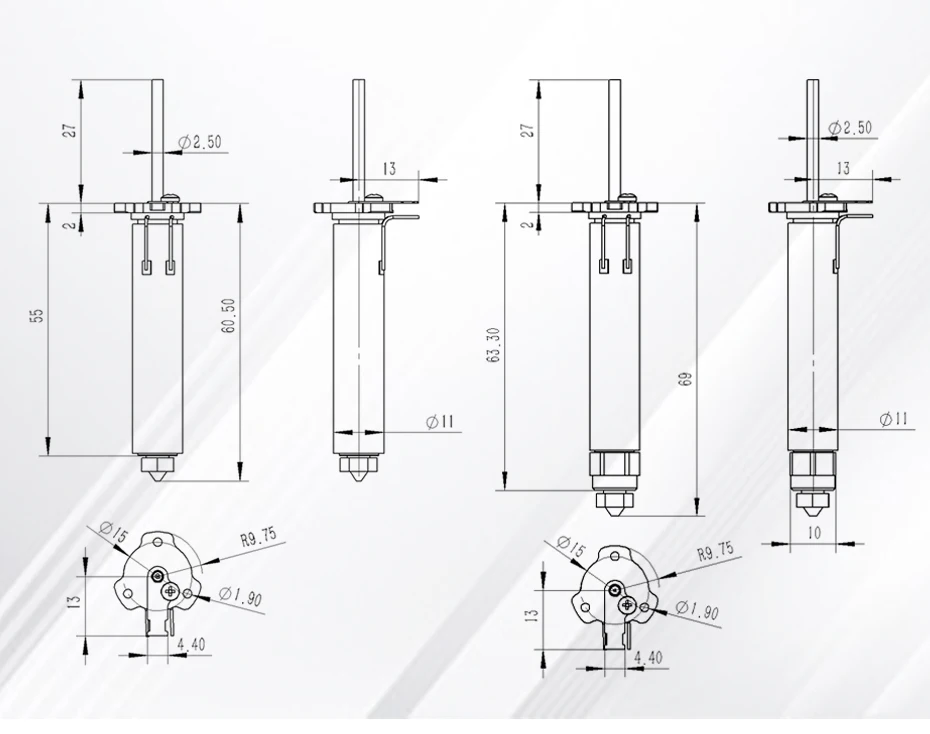

If you want to print larger parts and don't care about the details, you can use a larger diameter nozzle and melt zone extender to achieve a 63.3mm heating length, giving you a continuous maximum usable flow rate of 110 mm3/second ,to shorten the printing time as much as possible.

Thanks to the longer hot melt zone, the filament stays in the melt zone for longer and melts more thoroughly and evenly. the filament liquefaction is more complete after leaving the nozzle. This significantly increases the layer adhesion, so STD6 HOTEND prints stronger and more durable parts under the same conditions.

With multiple mounting points on the stainless-steel shield and mounting brackets, you can flexibly mount the ABL sensor and layer cooling fan without worrying about thermal deformation of the printed parts to the heat of the hot side. This simplifies the design of the print head, you only need to focus on fixing the STD6 body on the print head. That's all.

Composition

High quality component parts.

1.STD6 Ceramic Heating Core

2.Orbiter v2.0 Extruder

3.Part Cooling Fan (4510 DC24V)

Excellent compatibility

Excellent compatibility

Compatible with Orbiter V2.0 Extruder.

STD6-LC Support a wide range of sensors.

Compatible withBL Touch,M8,M12,M18 proximity sensor.

STD6 Ceramic Heating Core

*Built in RTD PT1000 Sensor

24V 144W Heater

High power cylindrical ceramic heating element up to 144W.

Thin Wall Heat Breaker.

Evenly heated thanks to cylindrical ceramic heating element.

One Hotend Two Configuration

Compatible with v6 and Volcano nozzle.

Detail Show

Adding to cart succeed!

items in cart.

Total:

Requires a minimum purchase of {MinPrice}. And you still need to meet the requirements.

Proceed to Checkout Return to Shopping